ANALYTICAL SERVICES

Focused on both service and scientific excellence, we continually track the evolving regulatory landscape to offer relevant and forward-looking constituent testing guidance to our clients. Regardless of your organizations size or the position of your product within its regulatory lifecycle, our team will produce a customized, resource-maximizing, and comprehensive constituent testing strategy that achieves your regulatory objectives.

Our team is proud to offer a wide arrange of high-quality scientific services to support your product’s regulatory needs.

CONTRACT

MANUFACTURING

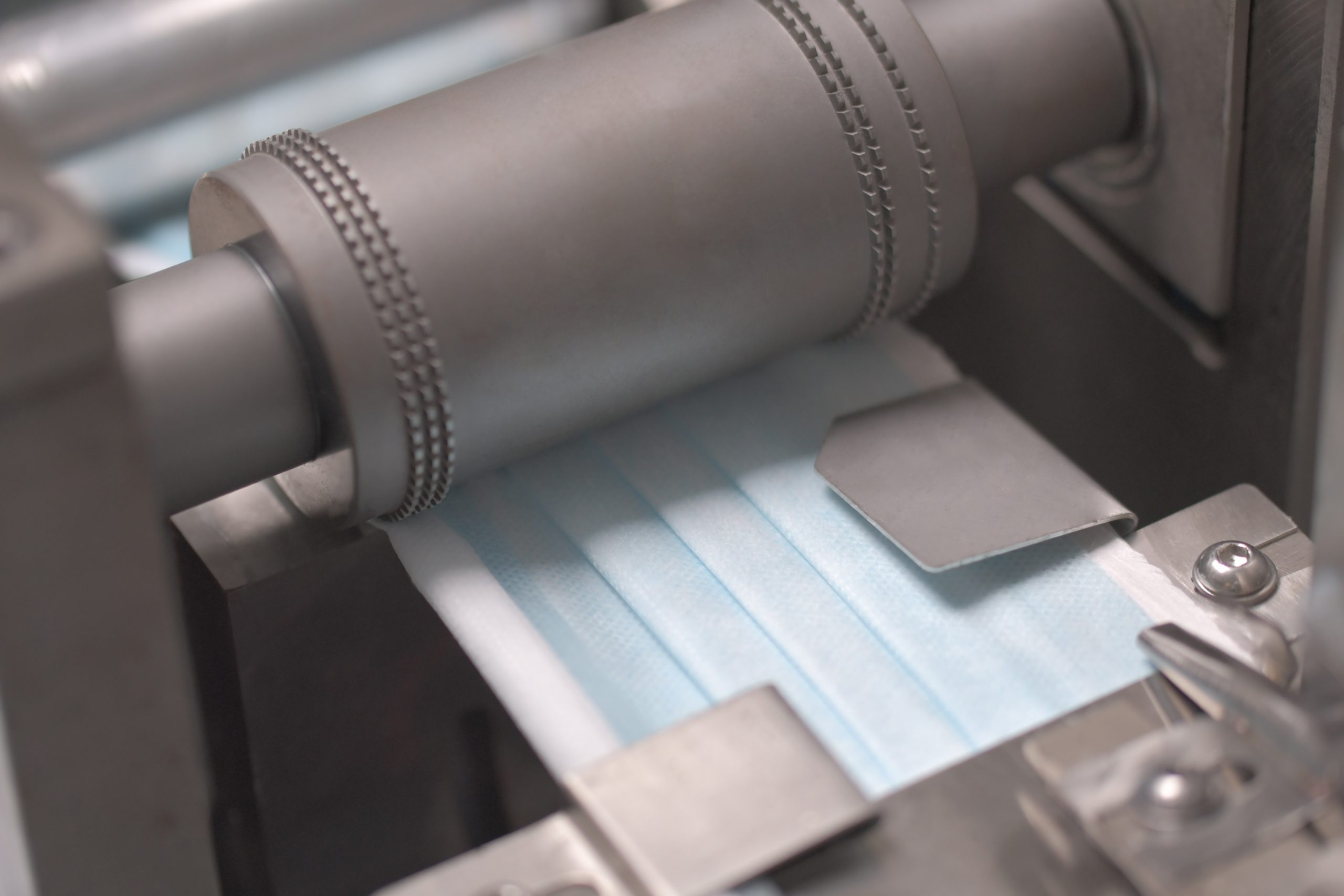

Angstrom Manufacturing, Incorporated is a privately held United States based business founded in 1999. We pride ourselves in being able to offer our clients solutions for their contract fulfillment needs with an emphasis on finished good manufacturing. When you choose to add Angstrom to your team, our 72,000 square foot FDA registered facility becomes a virtual extension of your company. We pride ourselves in our innovative use of automation and design. In fact, many of our clients already think of Angstrom as their own personal manufacturing and finishing department.

Whether your company is looking for concept to completion product assistance, or is just looking for help with one of the many steps along the way, our dedicated contract manufacturing team is trained and ready to make your unique business goals a reality both quickly and on budget.

CONTRACT MANUFACTURING

We pride ourselves in being able to offer our clients across various regulated industries turnkey solutions for their contract filling, contract packaging, and fulfillment needs. When you choose to add BRS to your team, our 38,000 square foot facility becomes a virtual extension of your company. In fact, many of our clients already think of BRS as their own, personal manufacturing and finishing department. Whether your company is looking for concept to completion product assistance, or is just looking for help with one of the many steps along the way, our dedicated contract manufacturing team is trained and ready to make your unique business goals a reality both quickly and on budget.

NICOTINE

SERVICES

TOBACCO-FREE

NICOTINE SERVICES

QUALITY YOU CAN TRUST

In the regulated product industry, one of the biggest concerns our clients have is making sure their products will consistently meet the high-quality standards that their customers have come to expect from their brand. As brand holders ourselves, we understand these concerns and fully appreciate the importance of this responsibility. This is why all products we develop are closely monitored throughout the manufacturing process to maintain the highest quality standards. As part of our quality process, all raw materials are meticulously audited by our quality control team upon receipt. Once the materials have passed inspection, your products will be developed in one of our two ISO 14644 Class 6 and ISO 1469 Class 7 certified clean rooms. Finally, each batch of finished goods is quality tested in our in-house ISO 17025 analytical lab with fully transparent lab results available to your team prior to product packaging and distribution.

Additional Quality Controls

- Temperature controlled manufacturing and storage

- Isolated and restricted access mixing and materials area

- Separate PPE dressing area prior to entering manufacturing space

- SAP ERP System utilized to control all facets of the business

- Robust supply chain vendor selection process requiring”

- Passing through in-house analytical testing

- Demonstration of lot-to-lot consistency

- Proven strong and prolonged financials

QUALITY YOU CAN TRUST

In the regulated product industry, one of the biggest concerns our clients have is making sure their products will consistently meet the high-quality standards that their customers have come to expect from their brand. As brand holders ourselves, we understand these concerns and fully appreciate the importance of this responsibility. This is why all products we develop are closely monitored throughout the manufacturing process to maintain the highest quality standards. As part of our quality process, all raw materials are meticulously audited by our quality control team upon receipt. Once the materials have passed inspection, your products will be developed in one of our two ISO 14644 Class 6 and ISO 1469 Class 7 certified clean rooms. Finally, each batch of finished goods is quality tested in our in-house ISO 17025 analytical lab with fully transparent lab results available to your team prior to product packaging and distribution.

Additional Quality Controls

- Temperature controlled manufacturing and storage

- Isolated and restricted access mixing and materials area

- Separate PPE dressing area prior to entering manufacturing space

- SAP ERP System utilized to control all facets of the business

- Robust supply chain vendor selection process requiring”

- Passing through in-house analytical testing

- Demonstration of lot-to-lot consistency

- Proven strong and prolonged financials